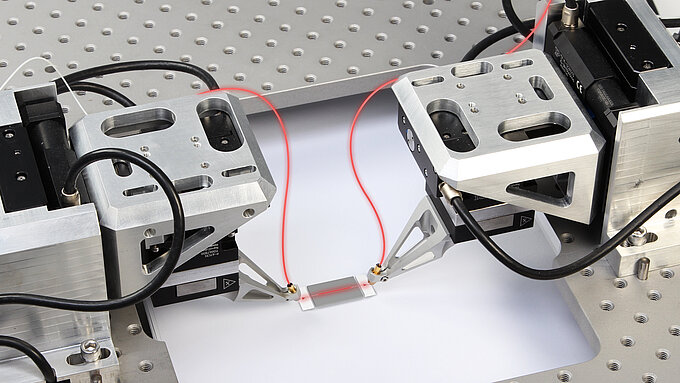

F-131 Powerful Fiber Alignment System

Ideal for Applications in Photonics

- Long lifetime due to NanoCube®

- Safety due to integrated sensor technology

- Long travel ranges to 15 mm

- Inexpensive

Fast and high-precision drives

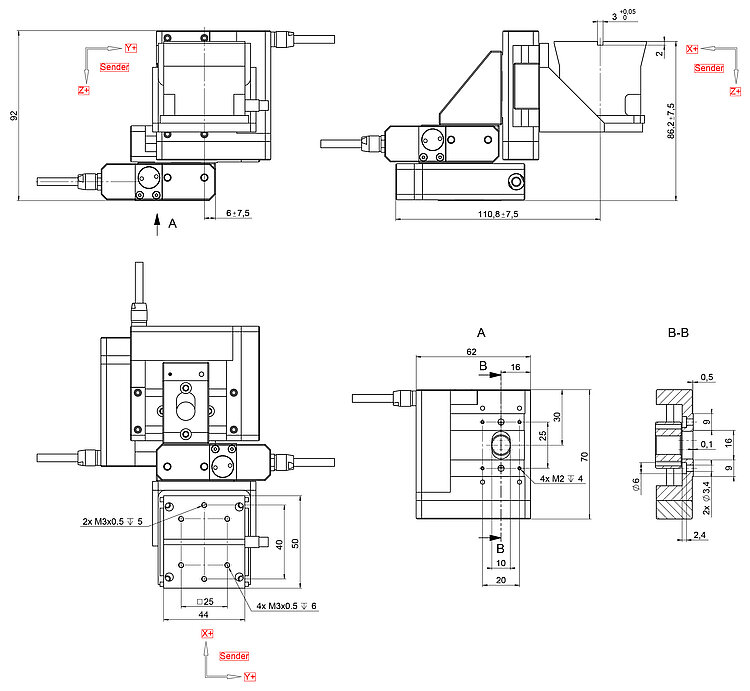

The basis of the fiber alignment system is an XYZ setup consisting of three motorized linear stages from the M-111 series for rough alignment and a P-611 NanoCube® nanopositioner. The motorized drives make longer travel ranges possible and at the same time, the NanoCube® nanopositioner ensures fast scanning motion and precision positioning. Flexure guides and all-ceramic insulated PICMA® actuators guarantee a long lifetime. Because all drives are equipped with position sensors, it is possible for example, to reliably prevent collisions with expensive silicon wafers.

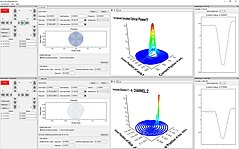

High-performance scan routines

The highly developed scan routine is integrated directly in the controller for controlling the P-611 NanoCube® nanopositioner. The performance is improved considerably and integration simplified. This allows ideal management of all applications where analog signal optimization is the basis such as for example, in the field of photonics.

Complete package

The fiber alignment system is supplied as a complete package with the required C-884.4DC and E-727.AS controllers as well as with extensive software including the PIMikroMove graphic user software for startup and operation of all PI systems.

Programming interfaces are included in the software package that allow the user to integrate a PI controller into their own user programs. The control of the positioning system therefore becomes part of the user program. Interfaces are available for all common programming languages including NI LabVIEW and Matlab.

Furthermore, there is an option to purchase the C-990.FA1 software. It provides a particularly convenient method for setting up the axes for scanning, performing the scans, and displaying the results.

Additional, high resolution analog input

The optical intensity signal is made available to the controllers directly via their analog inputs. The E-727.AS controller that controls the NanoCube® nanopositioner is equipped with an extremely high-resolution and high dynamics analog input. This makes it possible to acquire the optical signal quickly and precisely and find the maximum intensity automatically.

Application fields

Alignment of optical components, qualification of optical components in silicon photonics

Specifications

Specifications

Motion and positioning | F-131.3SD1 | Unit |

|---|---|---|

Number of active axes | 6 | |

Rough positioning | ||

Active axes | X, Y, Z | |

Travel range in X, Y, Z | 15, 15, 15 | mm |

Typical minimum incremental motion | 0.05 | µm |

Design resolution | 0.0069 | µm |

Typical unidirectional repeatability | 0.25 | µm |

Typical backlash X, Y, Z | 3 | µm |

Max. velocity | 1.5 | mm/s |

Sensor type | Rotary encoder | |

Guide | Ball guide | |

Drive type | DC gear motor | |

Fine positioning | ||

Active axes | X, Y, Z | |

Travel range in X, Y, Z, closed loop | 100 | µm |

Typical resolution, open loop | 0.2 | nm |

Typical resolution, closed loop | 1 | nm |

Typical linearity error, for the entire travel range | 0.1 | % |

Typical repeatability (bidirectional) | <10 | nm |

Sensor type | SGS | |

Drive type | PICMA® |

Downloads

Product Note

Product Change Notification F-130, F-131

Datasheet

Documentation

User Manual F131T0001

F-131.3SD1 X,Y,Z Alignment System

User Manual E727T0012

E-727.AS Digital Multi-Channel Piezo Controller With Area Scan Routines for Fast Optical Alignment in Silicon Photonics Production

User Manual PZ253

P-611 Nanopositioning Systems with Strain Gauge Sensors / without Sensor

User Manual M110T0032

M-110.x1 / M-111.x1 / M-112.x1 microtranslation stages

User Manual MS243

C-884.4DC and C-884.6DC Motion Controller for DC Motors and Brushless DC Motors, 4 or 6 Axes

3D Models

3-D model F-131.3SD1

Quote / Order

Ask for a free quote on quantities required, prices, and lead times or describe your desired modification.

Accessories

견적 요청 방법

Ask an engineer!

Quickly receive an answer to your question by email or phone from a local PI sales engineer.

적용 분야

SiPh Testing, Assembly, and Packaging

When it comes to throughput and production costs in testing, assembling, and packaging of photonic devices, alignment is one of the most significant cost factors. For maximum performance, the optimal combination of accuracy, speed, and intelligent automation is needed.

Hexapods in Microproduction

What do optical components and glass fibers in photonics, mobile devices, and high-quality wristwatches all have in common?