Langevin 트랜스듀서 사양

PI Ceramic은 Langevin 트랜스듀서 프로토타입을 제공하며, 고객과 협력해 특정 애플리케이션 요구 사항에 맞춰 개발을 진행합니다. 기계적 품질을 높이고 전력 소비를 낮추는 것을 중점적으로 고려합니다.

요청 시 맞춤형 트랜스듀서 버전 제공 가능

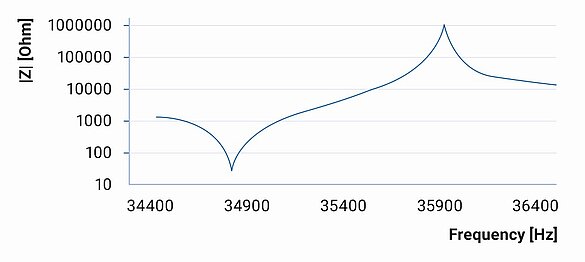

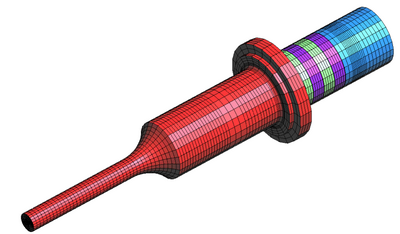

특수 애플리케이션에는 각각 고유한 요구 사항이 있습니다. PI Ceramic은 30년 이상 축적된 피에조 전문성을 바탕으로 최고 품질의 완전한 솔루션을 제공합니다. 당사의 서비스 범위는 애플리케이션별 컨설팅부터 >> 초음파 트랜스듀서 개발 및 제조, 그리고 적합한 구동 전자 장치 제공까지 다양합니다. 최고의 피에조 시스템을 개발하기 위해 PI Ceramic은 서브시스템 또는 완전한 솔루션을 제조하기 전에 가상 프로토타입을 제공합니다. 시뮬레이션은 당사가 고객과 더 빠르고 정확하며 경제적인 방식으로 합의를 도출할 수 있도록 해줍니다.

무연 피에조 세라믹으로 제작된 컴포넌트가 포함된 고출력 초음파 트랜스듀서

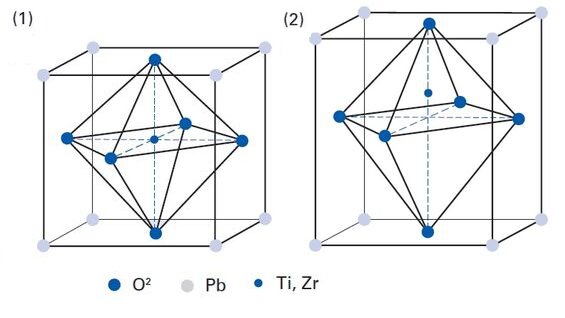

PI Ceramic은 PZT(납 지르코네이트 타이타네이트) 링으로 제작된 Langevin 트랜스듀서의 개발 및 제조뿐만 아니라, 무연 피에조 세라믹을 사용한 맞춤형 고출력 초음파 트랜스듀서 개발 서비스도 제공합니다.

칼륨-나트륨 나이오베이트(KNN)로 만든 링은 모든 애플리케이션에서 PZT 링을 대체하기에 적합하지 않습니다. 그럼에도 불구하고, 무연 세라믹 컴포넌트를 적용하여 조정한 트랜스듀서는 많은 애플리케이션에 적합한 사양을 충분히 달성합니다. 이를 위해 PI Ceramic은 무연 소재 개발에 대한 전문성과 고출력 초음파 트랜스듀서 개발 및 제조에 대한 다년간 경험을 모두 활용합니다.

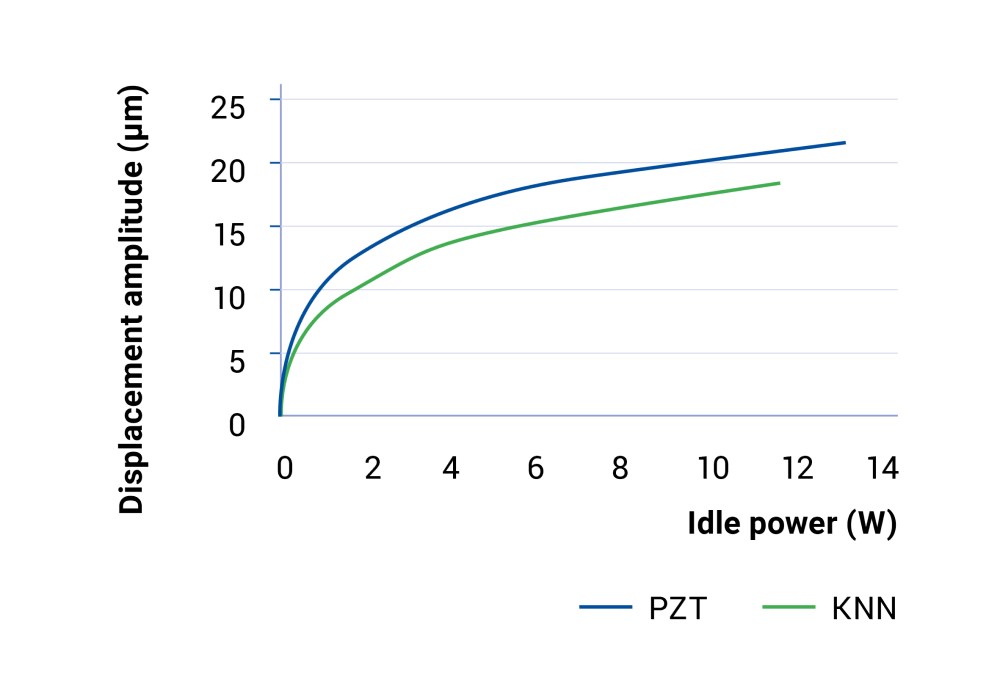

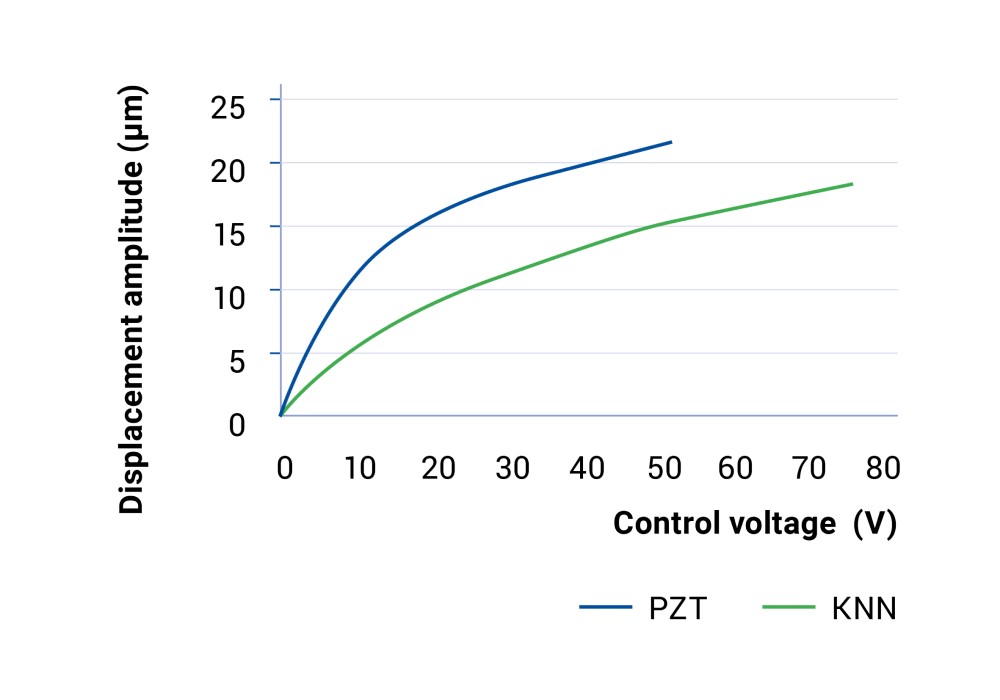

세포 용해 및 샘플 혼합용으로 사용되는 무연 및 기존 PZT 고출력 초음파 트랜스듀서의 비교 결과:

무연 KNN 초음파 트랜스듀서 프로토타입과 납 함유 PZT 링이 장착된 35kHz 트랜스듀서(무부하 상태)의 성능 데이터: 입력 전력의 증가에 따른 팁에서의 변위 진폭(왼쪽), 35kHz에서 제어 전압의 증가에 따른 팁에서의 변위 진폭(오른쪽)

>> 소재의 매개변수가 원하는 고출력 초음파 트랜스듀서 사양을 달성하는 데 결정적인 역할을 합니다. 무연 KNN 링을 사용할 경우 동일한 전력 수준과 동일한 전압에서 변위가 감소합니다. 이는 더 높은 제어 전압을 사용하여 보정할 수 있습니다.

무연 소재는 트랜스듀서 팁의 동일한 변위 진폭에서도 손실 계수가 더 높아 링에서 더 많은 열이 발생한다는 점에 유의해야 합니다. 또한, 전력 손실이 더 크기 때문에 자체 발열도 증가합니다.

무연 KNN 컴포넌트이든 PZT 컴포넌트이든, 당사는 기쁜 마음으로 귀사의 애플리케이션에 맞춘 특수 고출력 초음파 트랜스듀서를 개발하는 데 협력할 것입니다.

문의하기

귀사의 프로젝트 사양과 요구 사항에 대해서는 현지 PI Ceramic 영업 엔지니어와 상담하세요.